The 7-Second Trick For Premier Aluminum Llc

Table of ContentsFascination About Premier Aluminum LlcUnknown Facts About Premier Aluminum LlcThe 7-Second Trick For Premier Aluminum LlcThe 9-Minute Rule for Premier Aluminum LlcPremier Aluminum Llc Can Be Fun For Anyone

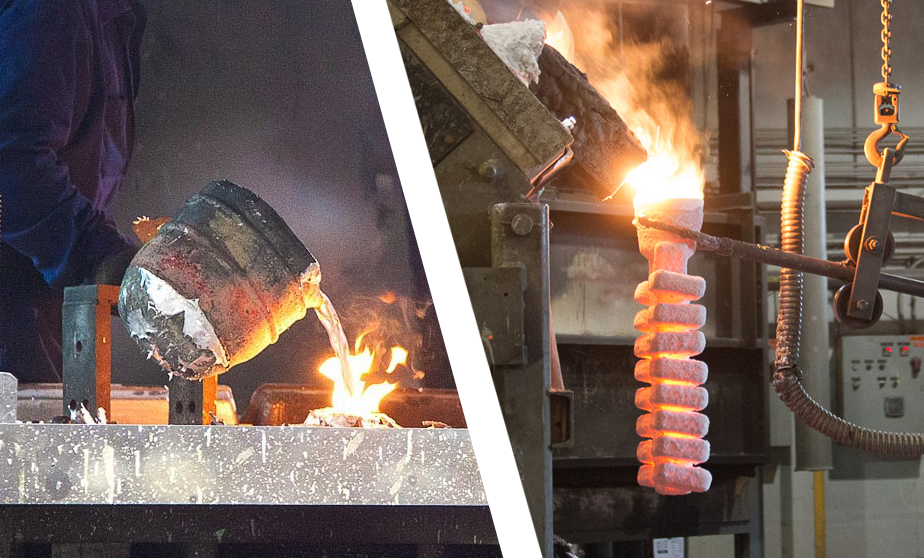

When picking an aluminum factory for your production demands, it's important to research numerous factors. One of one of the most vital facets to consider is the experience and skills of the shop. Picking a shop that has the right understanding of the light weight aluminum spreading procedure, and the profile to show for it, assists to have an effective result for your task.Having the experience and sector expertise to craft your spreadings for optimum manufacturing and high quality results will certainly improve the job. Producing aluminum spreading requires a facility collection of procedures to attain the appropriate outcomes. When choosing a new aluminum factory to partner with, guarantee they have substantial sector experience and are knowledgeable concerning all elements of the light weight aluminum spreading procedure: layout, manufacturing, material analysis, and product testing.

The shop needs to also have a tried and tested performance history of supplying outstanding products that fulfill or go beyond customer assumptions. Quality assurance should additionally be at the top of your checklist when picking an aluminum foundry. By working with a certified foundry that follows the criteria for high quality control, you can secure the integrity of your item and guarantee it satisfies your specs.

Top Guidelines Of Premier Aluminum Llc

This particular procedure can be automated and repeated. Numerous parts that really made complex shapes can be made using this process. Large quantities of parts can be produced in simply a short period of time. Prior to you start browsing for a dependable aluminum die caster, there are some vital things that you require to do first.

You need to ask yourself what kind of aluminum die spreadings you require. After identifying what you call for, you need to mention the specs of the light weight aluminum die castings you need. Determine the weight, density, size, and various other specs of the aluminum die-cast you require. It would additionally be far better if you can attract and show all the measurements of the light weight aluminum die-cast.

Do you know exactly how much cash you have to invest in the items? In order to do this, the best point to do is to figure out the amount of aluminum diecasts you require. After having this info, you can begin looking into aluminum die-casting manufacturers. You can do this by just keying the key phrase" Light weight aluminum pass away casting suppliers" on the Google internet search engine.

A few of the questions you need to ask yourself are whether they have actually experienced and trained drivers, for how long their service has actually functioned, or if they have some accomplishments. You can commonly obtain the responses to these inquiries from the supplier's internet site. You can research other internet sites or outside sources to verify if the details supplied on the manufacturer's internet site is genuine.

Premier Aluminum Llc for Dummies

Another point you need to take into consideration is the manufacturer's ability to generate light weight aluminum die-casting products. In other words, the quantity of products the maker can create at an offered time. Some of the essential concerns you require to ask on your own are whether the producer can create a higher quantity or can the manufacturer satisfy your needs.

(http://go.bubbl.us/e739a3/4118?/PastePremier-Aluminum-LLC)Suppose your firm requires 10,000 pieces of particular machine parts from the maker within one month? You got this quantity; however, the producer can only produce 5000 pieces of these machine components within one month (Casting Foundry). Consequently, you will not have the ability to get the quantity that you purchase in a timely manner

How Premier Aluminum Llc can Save You Time, Stress, and Money.

It is crucial that you ought to inquire if the maker is implementing an internal tooling process. In addition, you have to ask the producer just how much the cost of internal tooling is. The in-house tooling process, which allows you to produce unique designs and forms can be an extra cost.

This facet straight correlates with the producer's production capability. You have to seek a manufacturer that can ensure quicker shipment of products. This must be done in such a way that high-grade criteria are preserved. This can guarantee that you can get your items in a timely manner, and you can prevent missing out on those important business chances.

This indicates that there are several choices that you can pick from. Today, client needs keep on altering. It appears that customers are browsing for an excellent mix of high quality, cost-effectiveness, and longevity. That is why it is greatly suggested that you should choose a supplier that can generate various sorts of light weight aluminum die-cast products.

The Only Guide for Premier Aluminum Llc

The majority of commonly, these light weight aluminum die-casting products will certainly call for some designs, machining, or finishing touches. Having this in mind, you should search for a producer that can carry go right here out a range of additional completing works as soon as pass away spreading is done. Some examples of ending up procedures consist of Chromating, CNC Machining, Sandblasting, Powder finish, Anodized, E-coating, Damp paint, Plating, and a lot more.

Pass away casting is among the most affordable, accurate, and protean production processes in the world moment. The process involves suitable molten essence, under stress, into an appropriate die (earth), and previously solidified it can be expelled and ended up (if necessary) in a selection of methods. The dies are [...].